The space industry is entering a new era defined by speed, innovation, and collaboration.

Once dominated by government programs, space exploration is now driven by agile companies that build faster, test smarter, and adapt quickly to new challenges.

These innovators are reshaping how spacecraft are designed, launched, and operated beyond Earth’s orbit.

Among them, one company stands out for transforming how propulsion systems are created and tested, setting a new standard for efficiency and reliability in space mobility.

Building on the foundation laid by pioneers like Deep Space Industries, this article explains how Agile Space Industries is driving innovation in modern space propulsion.

The Origin and Growth Story of Agile Space Industries

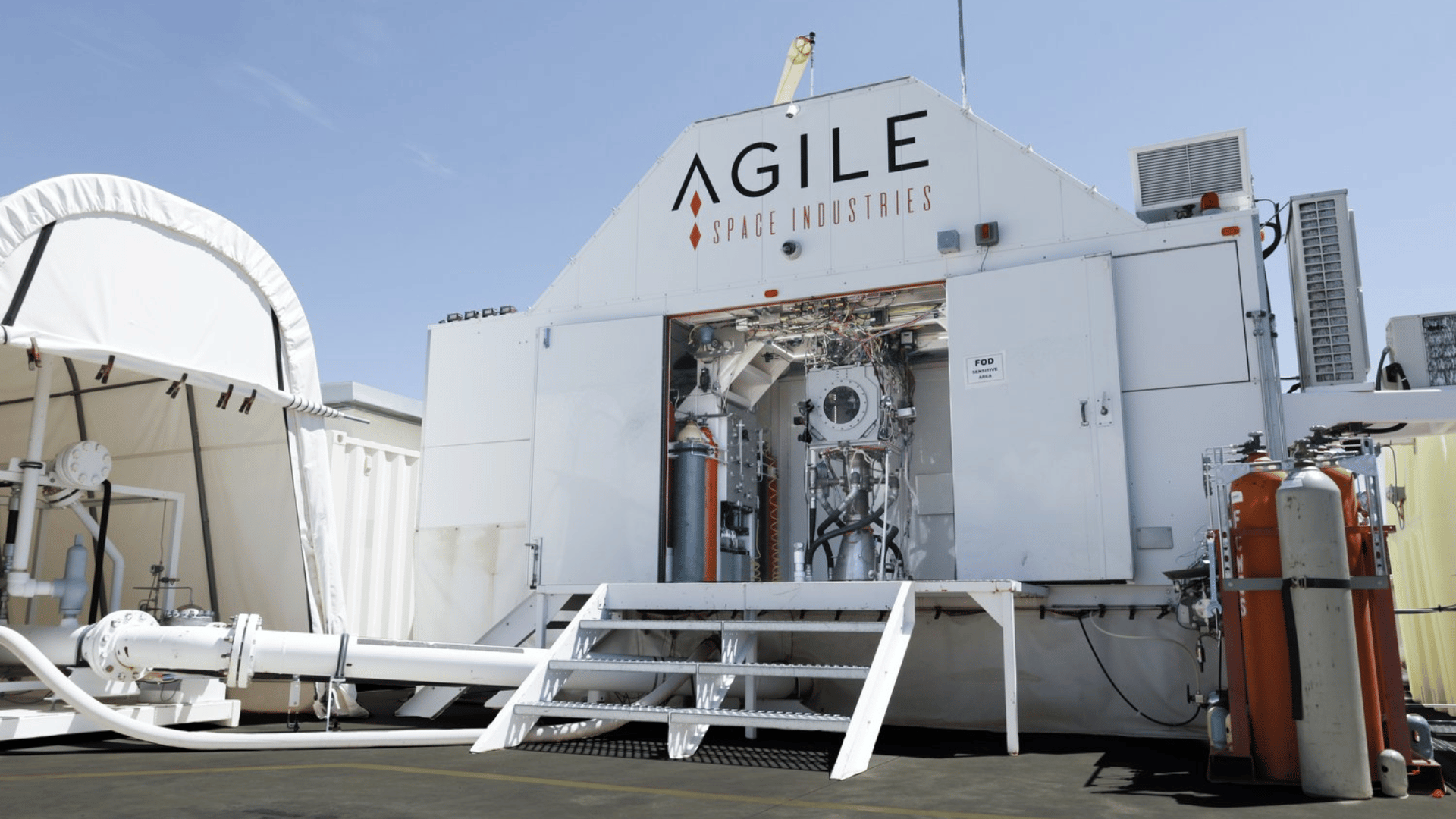

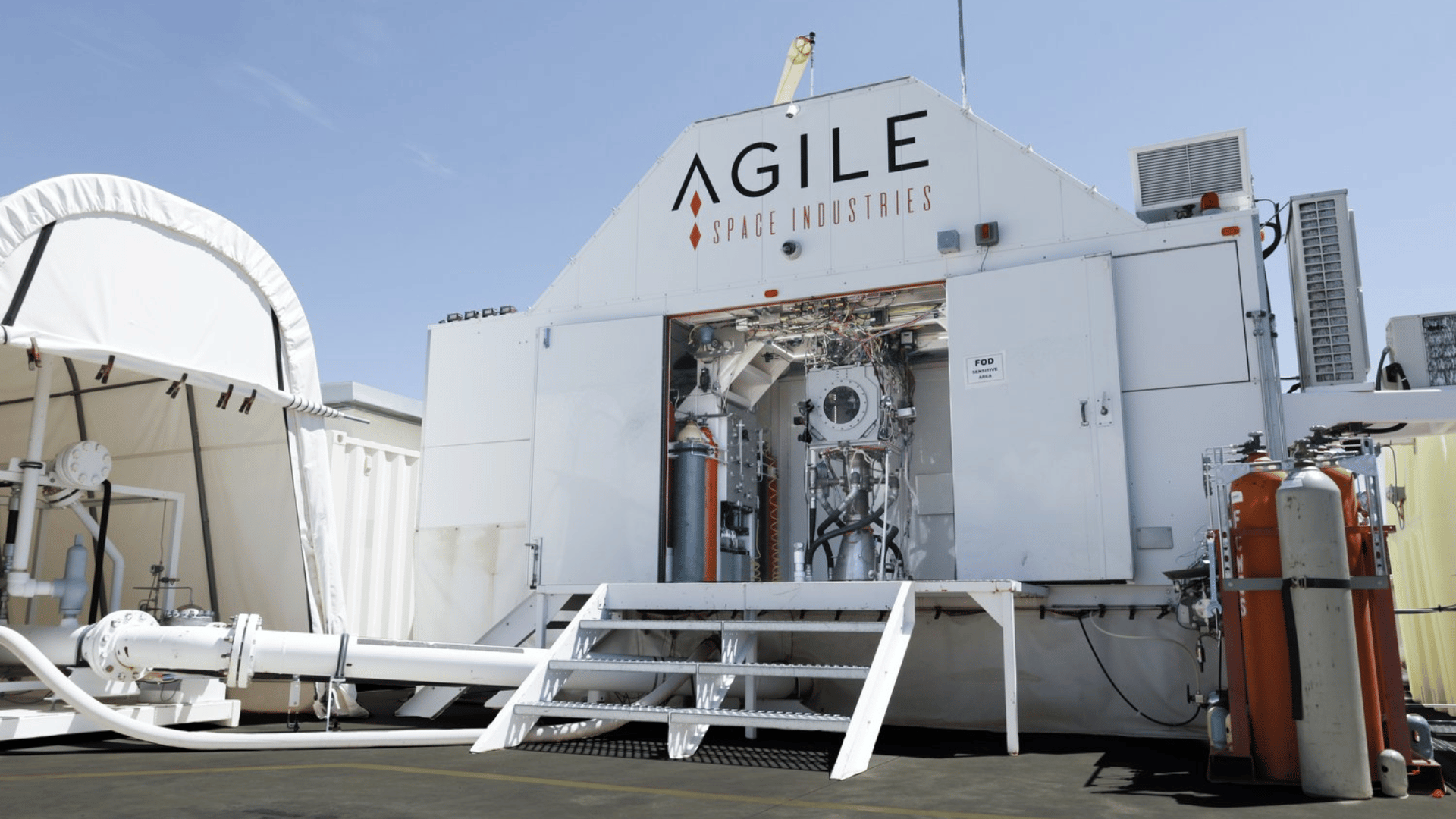

Agile Space Industries, headquartered in Durango, Colorado, began in 2009 as Advanced Mobile Propulsion Test (AMPT), a propulsion testing provider.

The company spent its early years perfecting high-precision hot-fire testing for thrusters used by NASA and commercial customers.

In 2021, Agile acquired Tronix3D, expanding its additive manufacturing capabilities and bringing metal 3D printing in-house.

Two years later, in 2023, Agile secured strategic funding from Lockheed Martin Ventures, cementing its position as a key supplier in the growing in-space propulsion market.

Today, Agile operates as a vertically integrated propulsion manufacturer, designing, printing, assembling, and testing its own engines all under one roof.

This structure dramatically accelerates development and allows the company to deliver mission-ready hardware in weeks instead of years.

What is Agile’s Core Technology?

Agile Space Industries builds propulsion systems that rely on hypergolic chemical reactions, known for their instant ignition and mission reliability. These systems deliver precise, dependable thrust for satellites, lunar landers, and deep-space vehicles.

Key Highlights:

- Proven Propellant Combination: Uses monomethylhydrazine (MMH) as fuel and nitrogen tetroxide (NTO/MON3) as oxidizer, trusted for reliability, storability, and precise control.

- No Ignition System Needed: Hypergolic fuels ignite on contact, reducing system complexity and increasing mission safety.

- Ideal for Critical Missions: Designed for applications where precise maneuvering and long-term storage are essential.

Example: DS250 Thruster

- Rapid Development: Designed and built in just 10 weeks for The Exploration Company’s Nyx spacecraft.

- High Performance: Demonstrated exceptional thrust efficiency, pulse-mode control, and thermal stability.

- Thoroughly Tested: Validated through extensive hot-fire testing at Agile’s Durango facility, confirming flight readiness and durability.

- Proven Agility: Showcases Agile’s ability to move from design to qualified hardware in record time.

Agile Manufacturing and Testing

Image Source: Oklahoma Business Voice

Agile integrates additive manufacturing (3D printing), data-driven engineering, and on-site hot-fire testing to create a seamless development loop.

| Capability | Overview | Key Benefits |

|---|---|---|

| Additive Manufacturing | 3D prints engine chambers, valves, and injectors using aerospace-grade metals. | Faster prototyping, lower cost, and rapid design iteration. |

| In-House Testing | Operates full-scale test stands simulating real space environments. | Immediate feedback and faster validation cycles. |

| Design Flexibility | Uses digital twins and simulation tools to optimize performance before printing. | Shorter time to flight and higher reliability. |

By controlling every stage of production, Agile avoids supply-chain delays and ensures consistent quality, a critical advantage in today’s fast-paced space industry.

Key Partnerships and Collaborations

Agile Space Industries strengthens its innovation through targeted partnerships that enhance its technology and market reach.

1. NASA and Government Collaborations

Agile maintains strong relationships with NASA and the U.S. Department of Defense, working on propulsion testing, performance validation, and component development.

- Rigorous Standards: Agile’s thrusters and components undergo evaluation under NASA and DoD testing frameworks, ensuring compliance with the highest aerospace performance and safety standards.

- Advanced Research Support: These programs provide access to government expertise and testing facilities, allowing Agile to refine its systems for deep-space and defense applications.

- National Mission Contribution: By supporting both commercial and government programs, Agile helps enhance the reliability of U.S. in-space mobility and propulsion capabilities.

2. The Exploration Company (Nyx Spacecraft)

A standout example of Agile’s agility in execution is its partnership with The Exploration Company, a European spacecraft manufacturer.

- DS250 Development: Agile designed, built, and qualified the DS250 thruster in just 10 weeks for integration into the Nyx spacecraft, demonstrating unmatched development speed.

- International Collaboration: This project bridged U.S. and European aerospace innovation, proving Agile’s capability to serve global clients with precision and flexibility.

- Mission Readiness: The DS250’s successful hot-fire testing validated its performance metrics, thrust efficiency, thermal control, and pulse-mode operation, cementing Agile’s reputation as a dependable propulsion partner.

3. Strategic Investment by Lockheed Martin Ventures

In 2023, Agile secured a strategic investment from Lockheed Martin Ventures, a milestone that marked a major step in its growth trajectory.

- Financial and Technical Backing: The investment provides both capital and access to Lockheed Martin’s deep aerospace network, supporting Agile’s expansion and scaling of its manufacturing operations.

- Future Mission Alignment: The collaboration positions Agile to contribute propulsion systems for upcoming lunar, cislunar, and deep-space missions, aligning with NASA’s Artemis program goals.

- Validation of Innovation: Lockheed Martin’s confidence in Agile underscores the company’s credibility as a next-generation propulsion provider capable of delivering mission-critical hardware with rapid turnaround.

Why Agile’s Approach Works

Traditional propulsion development often spans five to ten years. Agile compresses that process to as little as 18–36 months, leveraging its integrated testing and manufacturing model.

Key factors behind this success:

- Rapid Iteration: Continuous prototyping and real-time data feedback.

- Vertical Integration: Design, manufacturing, and testing under one roof.

- Data-Driven Engineering: Telemetry and analytics guiding every design improvement.

- Mission Agility: Systems tailored for diverse platforms, from cubesats to lunar landers.

This unique combination of speed and reliability positions Agile as a cornerstone of the modern in-space economy.

Next Steps in Propulsion Innovation

While its current flight systems rely on hypergolic chemical propulsion, Agile is actively researching dual-mode chemical-electric systems.

These next-generation engines will combine the high thrust of chemical propulsion with the efficiency of electric propulsion.

This will allow spacecraft to switch modes depending on the mission phase, using high-power burns for orbital insertion and low-thrust electric operations for cruise or station-keeping.

This research represents Agile’s commitment to long-term innovation without compromising its core reliability today.

Conclusion

Agile Space Industries has evolved from a propulsion testing company into a leader in advanced in-space propulsion systems.

By combining hydrazine-based chemical thrusters, additive manufacturing, and vertical integration, Agile delivers flight-ready engines faster and more efficiently than ever before.

Its real-world achievements demonstrate both technical excellence and true agility.

As the space industry continues to expand, Agile Space Industries stands ready to power the missions that will define humanity’s future in space, one precise, hypergolic thruster at a time.